Leak Control Management Procedures

What Can WE Repair

No:

- Hot Work

- Shutdown

- Isolate

- Nitrogen

- Spares issues

Repair:

- Carbon Steel

- Stainless

- Alloy

- FRP

- Copper

- Cast Iron

- Thermoplastics

The frequency of accidents involving hot works within the Oil and Gas, Maritime industry is on the rise. These accidents caused loss of lives, properties and seriously impede efficient production reliability. Many of these hot works related accidents are caused by routine maintenance programs aim at prolonging the service life of process assets and infrastructure.

Unfortunately, such dangerous hot works maintenance programs are carried out in a sporadic and unplanned approach, and often accompanied by frail safety assessments.

Based on the infamous “Hierarchy of Hazard Control”, the best solution is to totally eliminate the risks. The use of innovative “cold works composite technology” can effectively restore the integrity of pipe, tank and vessel work design parameters without the usual stresses associated with halting the process production and performing dangerous hot cutting and welding.

With the recent expansion and partnership with Government based research entities, the experience in this arena has now been enhanced to an elevated level, supplemented by Science, Research and Laboratory Capability.

We have a brave vision to help the world develop materials out of Non - Metallic Circular materials into High Value Assets that will not corrode and depreciate for use in Oil and Gas, Offshore and future energy initiatives in areas of Carbon Capture and Storage and Hydrogen – well renowned for its high corrosivity and explosive risks. The change will spearhead the energy sectors into making the world a safer and less pollutive place for future generations.

Fiberglass Piping/Tanks

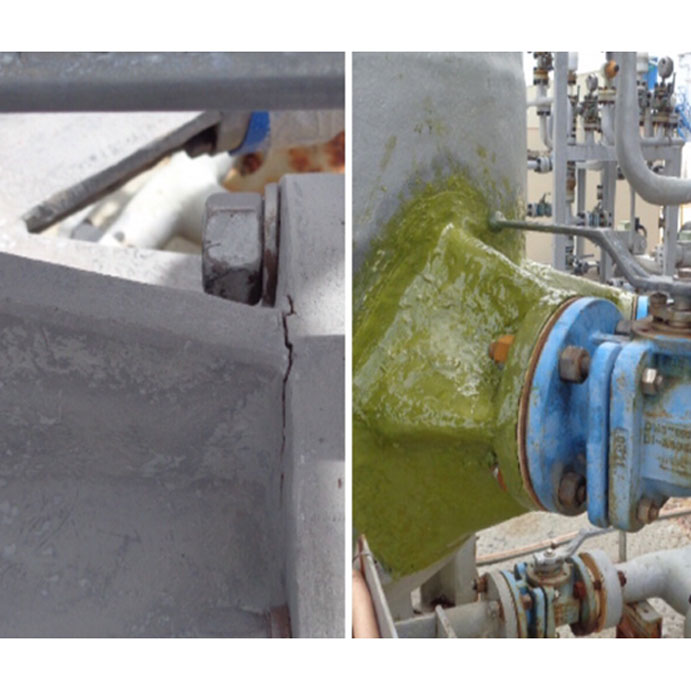

Severely corroded pipelines

Fuel System Leak Permanent Repair (Cold Works)

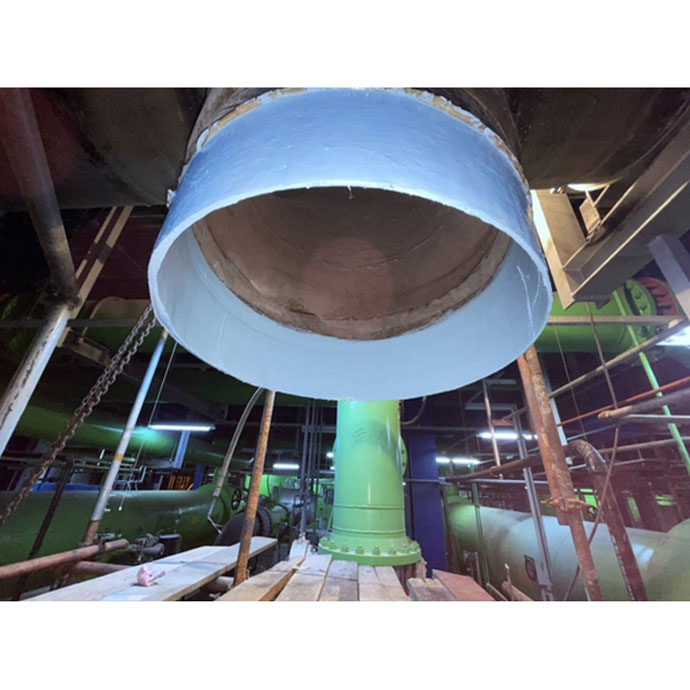

Soil to Air/Drain Pipe Repair Online

Online Tank Leak Repair (Wall)

Online Tank Leak Repair (Roof)