Pipe Cold Weld

ASME B31 Code for Pressure Piping (B31) provides simplified requirements for the safe design of various pressure piping system applications. The Sections of the B31 Code for Pressure Piping include the requirements for the following: Power Piping (B31.1), Process Piping (B31.3), Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids (B31.4), Refrigeration Piping and Heat Transfer Components (B31.5), Gas Transportation and Distribution Piping Systems (B31.8), and Building Services Piping (B31.9). The B31 simplified requirements were developed with and retain a focus on high-pressure, high-temperature piping which is typically welded or flanged. ASME B31 simplified rules are not developed as thoroughly regarding the design, manufacture, and installation of safe piping systems using non-welded, proprietary fittings (nonstandard components), such as the Lokring™ fitting with Elastic Strain Preload® (ESP® ) technology. However, there are B31 rules developed for pressure design and the development of stress multipliers (stress intensification factors) for nonstandard components that will allow the organization using Lokring fittings to develop a B31- compliant design.

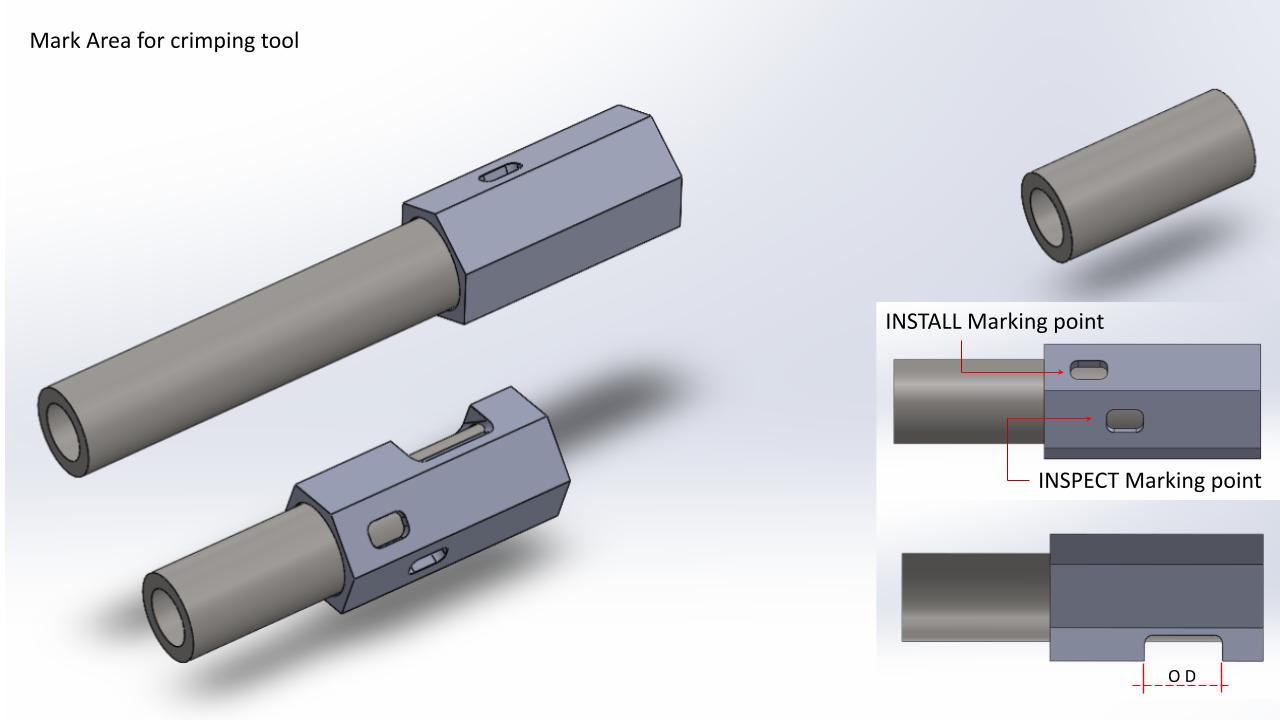

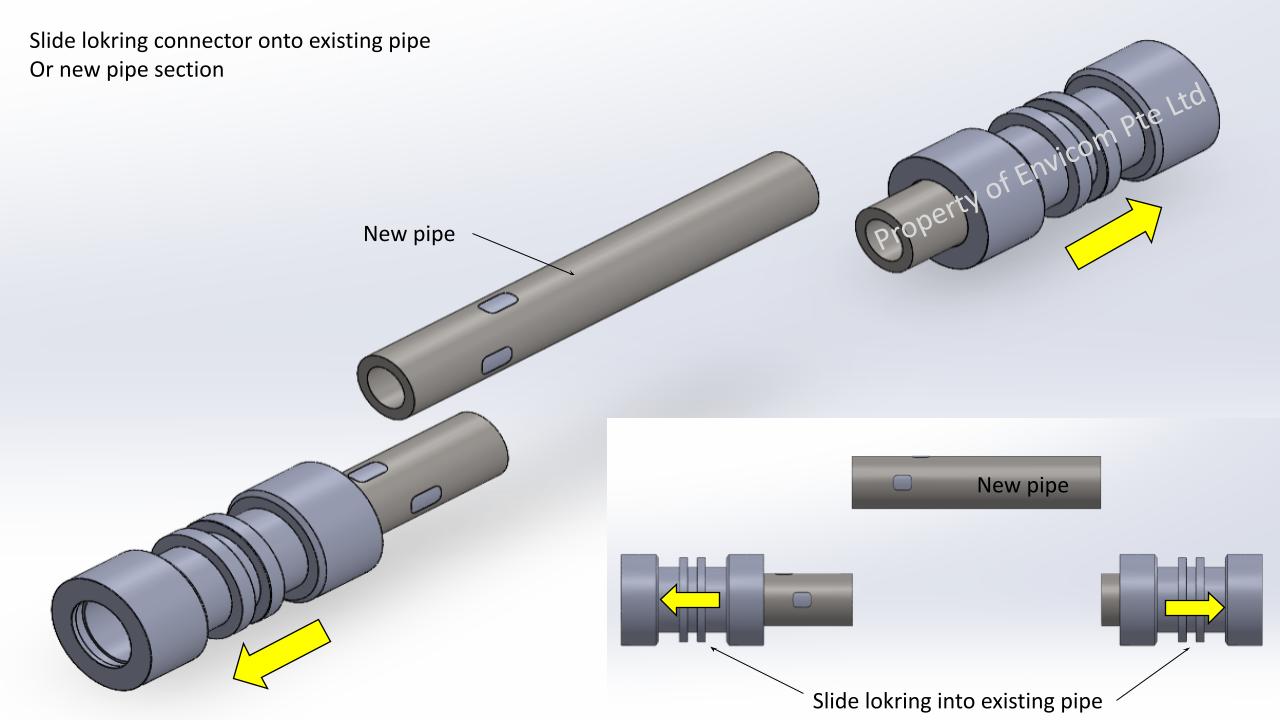

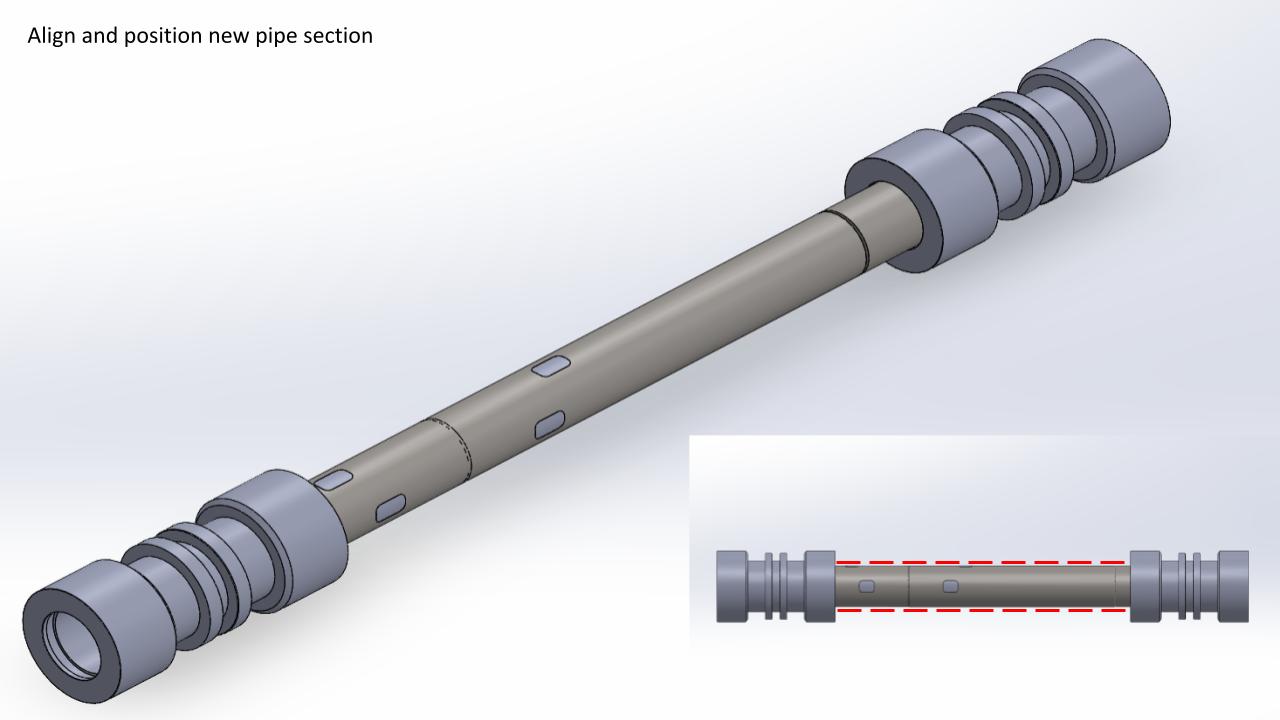

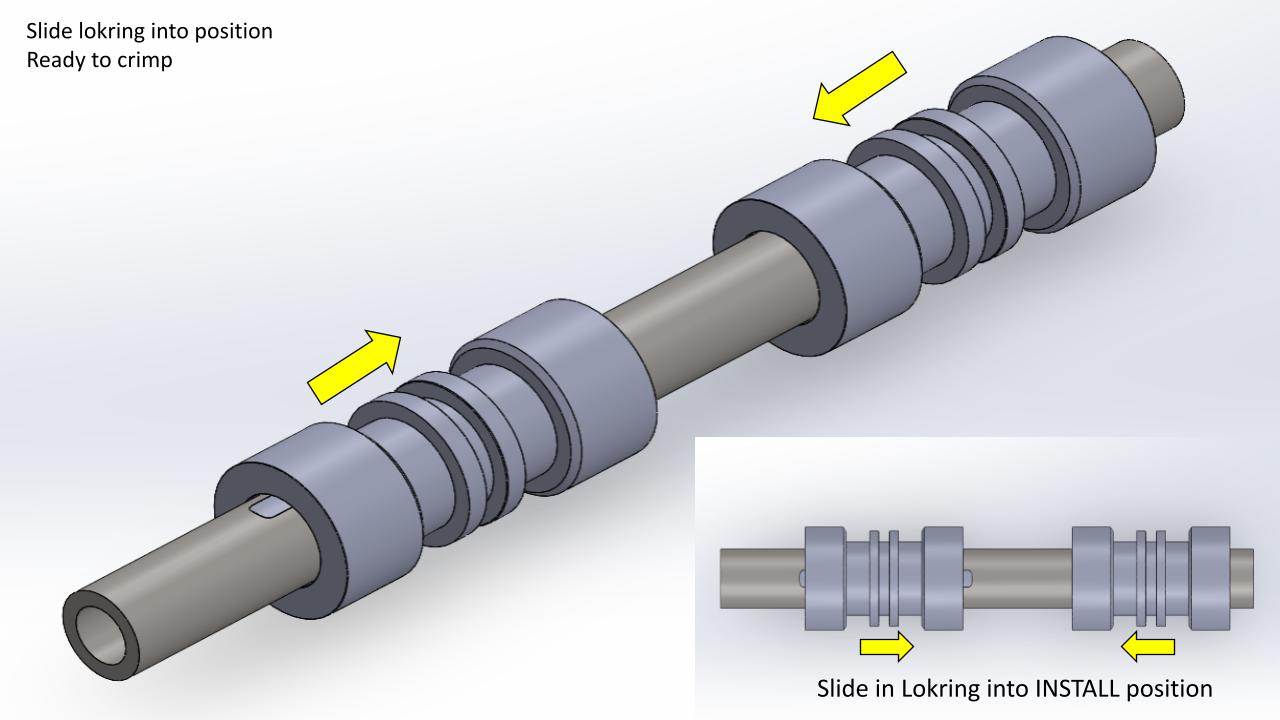

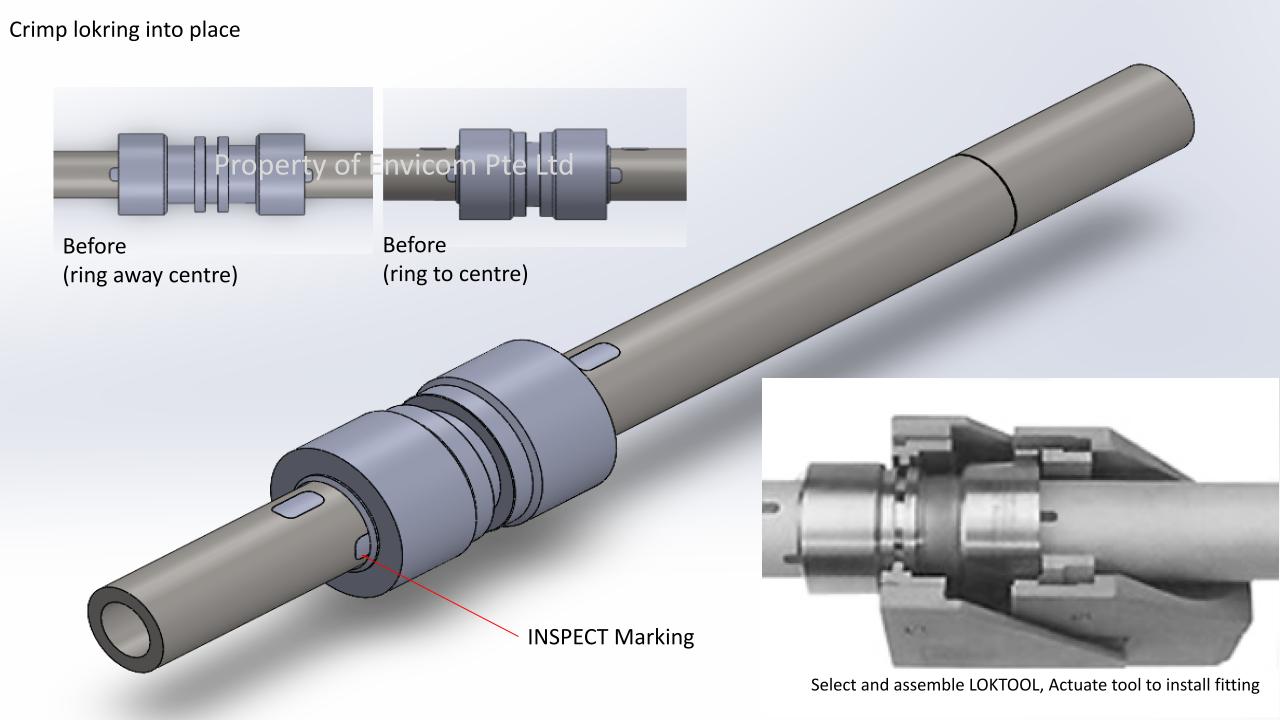

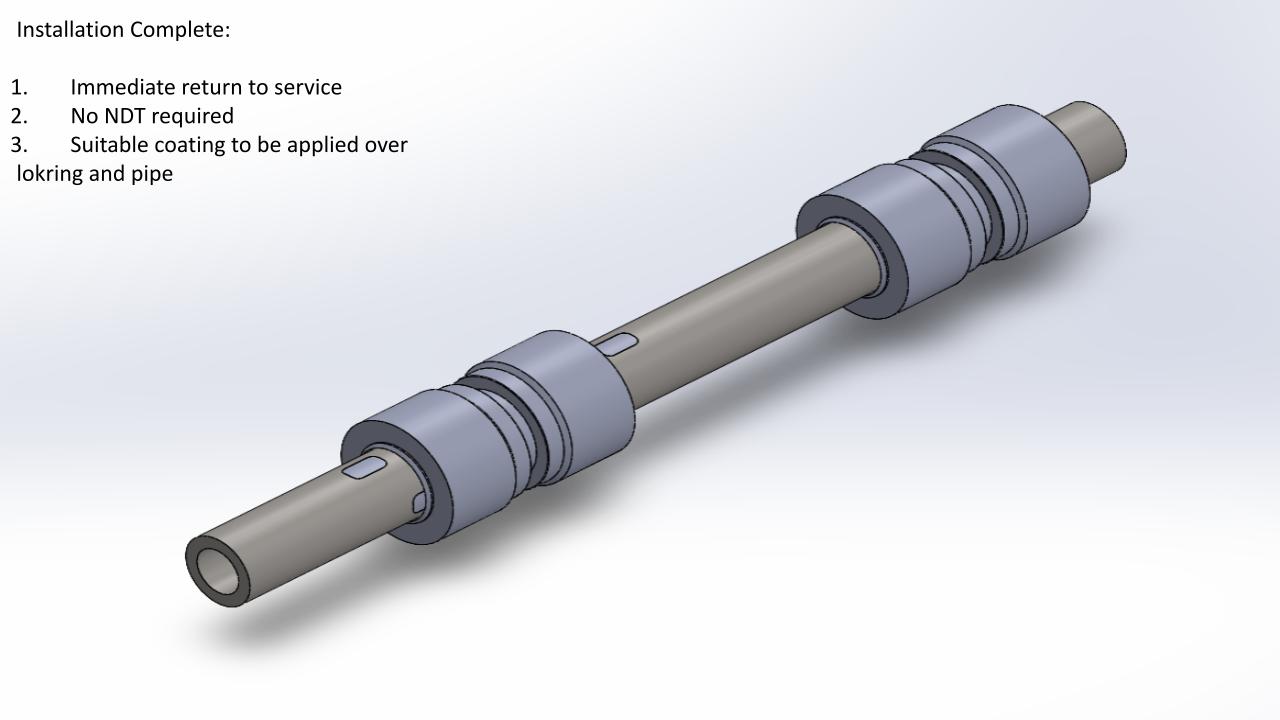

Lokring fittings use a patented, Elastic Strain Preload (ESP) technology to permanently join small diameter pipe (NPS 1/4 to NPS 4) and tube (1/4 to 2 1/2 inch OD) without threading or welding. Following insertion of the pipe end into the fitting, hydraulic tooling is used to advance each drive ring axially over the fitting body, radially compressing (swaging) the fitting body on to the outside diameter (OD) of the pipe. As the pipe is compressed, first elastically and then plastically, by the swaging action during installation, circumferential sealing lands machined in the bore of the fitting body grip and seal on the pipe OD, forming a gas-tight, metal-to-metal seal without O-rings or other elastomeric seals.